Behind the Scenes: October 2021 Update

This month we take our tour with three special guests: the project superintendents, Kris Koenig, Hutton; Mike Katt, BHS Construction; and Drew Deeters, BHS Construction.

Now entering October, behind the scenes progress informs us that electricians are in the process of bringing permanent power to the site, installation of the hydronics heating system is being completed and the building’s exterior is being buttoned up to prepare for the winter months and assemble the scaffolding to work on the interior finishes.

Welcome back to the Immaculata Church Project here in St. Mary’s Kansas. Today we're going to give you some updates, and we have three special guests: our project superintendents that are going to take us through some of the details with the stone and brick, a lot of our interior concrete work, and some special views that you can't see from the road in the back on the roof.

I'm here today with Mike Katt, one of our project superintendents. You might remember Mike from a video we did last October, a year ago. In the video, Mike and two other superintendents were laying out the footings with their total station. Since then you can see behind us here a lot has changed in a year and we're going to ask Mike what's gone on here over the last month.

[Mike] Well we have gotten a little bit higher on our cast stone here, on the north transept. In that time, we have had all the parts and pieces to go ahead and top it out, designed, made, and brought out on site, which is behind us.

[Bill] I see the hydro mobile is up to where the base for that cast statue will be, is that being installed soon?

[Mike] Yes actually, tomorrow our crane will mobilize from where it's currently sitting to up here on this hill and will assist the masons in setting that as well as the rest of their stone picks.

[Bill] All right, that'll wrap up this north transept? [Mike] Yes.

[Bill] All right let's move to the west and kind of let's talk about what these guys are doing over here.

[Mike] So they have built up their scaffold all the way to the top to get our cornice installed and they have built up scaffolding on the inside of the baptistery to get the upper cupola masonry installed.

[Bill] Okay so that lantern will be all brick and cast stone up there?

[Mike] Yes sir. As you can see on the side chapel we started with our water table cast stone and started bringing it around and they are going to start bringing the rest of that masonry up and tying it all back together.

[Bill] So that is the electrical transformer Mike?

[Mike] Yes, so Heineken came in and set that last week and they are actually down closer to (St. Mary’s Academy & College) campus making it up and we should be bringing permanent power into the building here fairly soon.

Since last video we've filled our stair pans all the way up to the choir loft.

[Bill] All right let's go up and take a look. We're going to go through the south tower here, go out and check out the choir loft and cry room.

[Mike] We have all of our temporary handrails here just to keep it safe for construction purposes.

[Bill] Okay so the workers can use these now instead of the stair tower we had set up inside? [Mike] Absolutely. And here at the cry room we do have our risers poured over our geofoam ready so all the pews will be set up here and have full view.

[Bill] All right let's walk on through to the south tower. And now let's go on up to the choir loft and take a look up there.

[Mike] A few air handling unit pads poured up here as well.

[Bill] It's a nice view from here. [Mike] You can see a long, long ways. So up here we have concrete over our geofoam steps similar to what we saw down in the cry room only at full length for the choir. [Bill] And this is all stepped back so that we have line of sight to the altar. [Mike] Yes.

[Bill] All right, well let's head down the north stair tower and let's go check out the south side of the building. [Mike] Okay. So over here on the south façade we do have waterproofing caught up to the side chapels, and as you can see the masonry on the south transept has also about caught up to the north one.

————————————————————————————————————————-

[Bill] Now we're here with Kris Koenig our lead superintendent for the project and we're going to talk about strategy going forward. So Kris, what is our strategy here going into these fall and winter months?

[Kris] So you touched on it a little bit in the last video, right now our biggest thing is kind of getting our exterior envelope wrapped up. The idea that we would have 100 percent finished this Fall is probably not true but we do need to get to where we can control our heat and we can shed water. And we've got a lot to do over the next two months but we're heading in that direction. We're going to start bringing our staging in, we'll start doing some of our paving from coming up from Gideon's road and ultimately we don't need as big of a footprint here to keep building on the building we'll actually come in and we'll pave this south road if we can get into it this Fall great, if the weather turns on us we'll hit it right coming out of Spring. And inside the building while we're focusing on the shell we are starting to move things into a transition to get ready for this next step.

[Bill] All right let's go take a look in there. [Kris] So you guys started to see in the last month's video but we are pushing to get in our hydronic system and our floor slab. That needs to get done for a couple of reasons and it's being driven by the interior work. Soon we're going to need to bring in a scaffold system that allows the interior finishes to go on this, so the concrete work inside this building we need to get it buttoned up to where once we start running the scaffolding through this system we've got an opportunity to do it. Nothing gets easier when we're doing that portion of the work.

[Bill] Yeah over the past weeks I’ve seen a lot of concrete trucks up here, you guys have poured a lot of concrete in the last few weeks. [Kris] Now we’ll continue pressing through all the interior concrete work for the next probably two-three weeks and then we'll start rolling it to the outside finishes. You can see they've started to tie in the main stair system. Our steel guys are focusing on the exterior shell whenever it's not windy, we go up, we get decking down and we have been fighting the wind, unfortunately, whenever it's too windy we come back in and we detail towers and we get the stairs in place.

[Bill] So this topping slab is done?

[Kris] Yep, our nave topping slab with the hydronics are in it; we'll actually pour the narthex tomorrow, and then again the focus being that we're in the middle of doing a little bit of everything we'll come back in and we'll take and do elevation shots from one side of the church to the other on this topping slab and kind of verify where things are at. We need to get things in a condition to where when we come back to this in almost a year's time and get into the stone flooring in it, we know where it was at before we did that.

[Bill] It looks like a lot of work has been done in the sanctuary and side chapels.

[Kris] Yeah last month we were just getting into the transept portion of the topping but they've gotten the front steps to the sanctuary and a couple of risers in and then they're putting in the main slabs of the two side chapels today. We've got another two pours to get essentially everything encapsulated in concrete but we will go ahead and push in the risers that go around the altars in all three of the sanctuary and the side chapels.

[Bill] All right, good!

[Kris] Again while we may be doing a little bit of everything right now and we've got focuses on big steel, interior, framing, concrete, our critical path right now is hard and heavy into the exterior shell. We really only have a couple months to get ourselves buttoned up. A lot of the framing is in place, we're ready for our sheathing, we're in the middle of transitioning from our roof trusses to our decking to our roofing. That is our critical path right now, we need to be able to control our outside.

————————————————————————————————————————-

[Bill] All right we're now here with Drew Deeters our third superintendent, one of the three superintendents that's been running this project from the beginning. Drew was also in that early October video, last year you saw him. He's going to take us up and run us through this critical path item, the roof, getting this thing dried in.

[Drew] Well we'll be nice and safe and smooth up here today. [Bill] Awesome. [Drew] It's great, today’s the first halfway calm day we've had in a while.

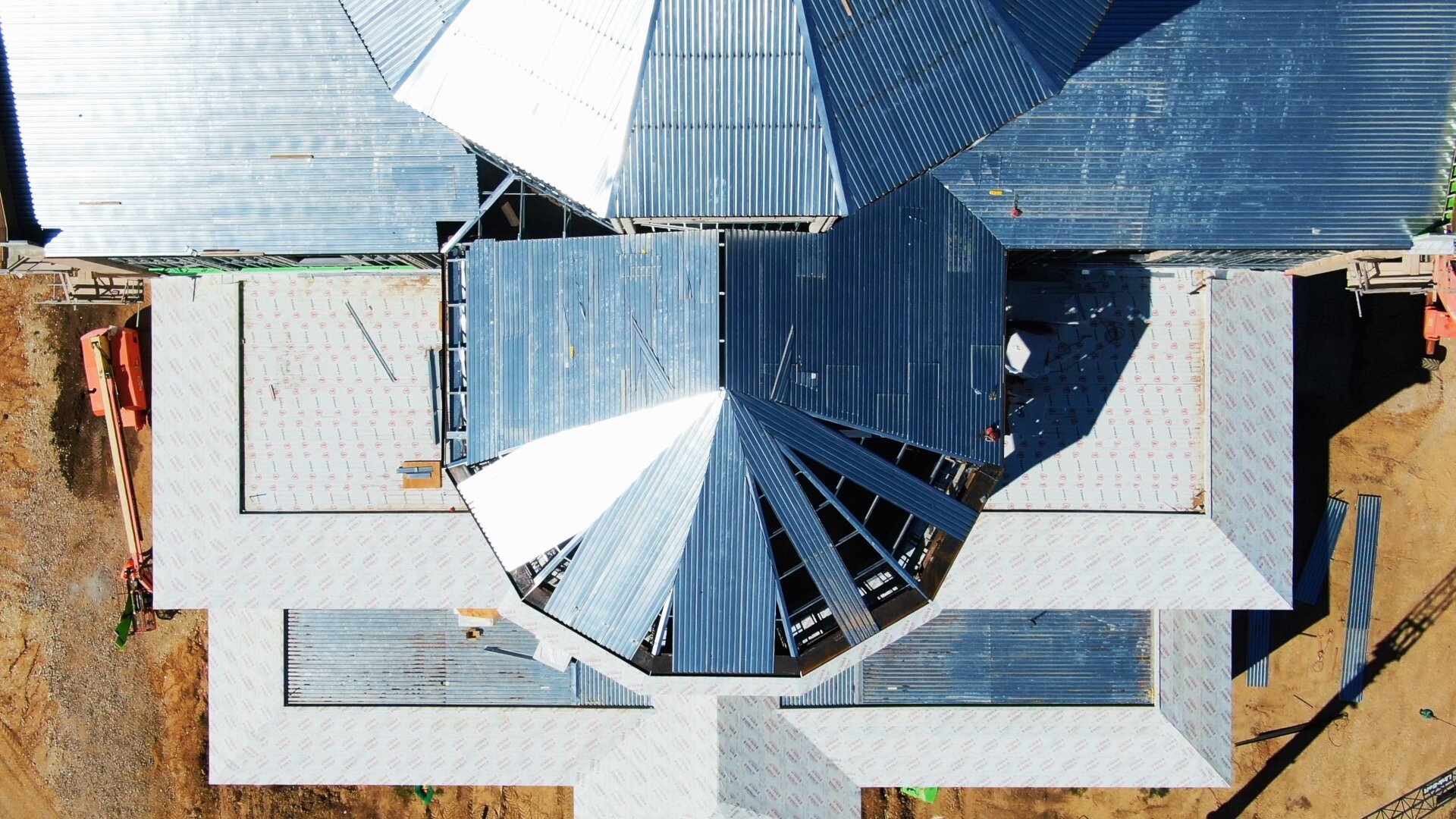

[Bill] So Drew, tell us a little bit about this roof system and what it's made up of. I know we have our structural steel and our light gauge trusses and there's a sheeting on there, take us from there.

[Drew] Yeah so after the trusses and decking are installed we go around with a heavier gauge deck angle, after that line is established the roofer can come in and build his roofing to that. It's a built-up insulation system roofing about six inches thick. On top of that like you can see on that piece there is a plywood on top and then they come over with this ‘ice, wind and water shield’ and put it over top to give us a good roof system and on top of that we'll go either a TPO roof on the flat roofs or a standing seam metal roof on the pitched roofs.

[Bill] Okay so this here's the product that will dry us in for the winter until all of the stucco work and exterior work is done and they'll finally put the roof? [Drew] Yeah, correct so we can actually come in when they get ready after we get DensGlass over our metal studs here they can come in and we can build our exterior scaffold system right on top of this roof here.

[Bill] Okay, so as far as scheduling I mean I see this back of house area is dried-in, there's a lot of roof to go and it's October and I know the goal is to have it by winter dried in there's, a lot of … this is a big critical path item, isn't it?

[Drew] Yeah, it's a huge critical path item to make sure we can shed water by winter and shed ice by winter and try to get this building halfway climatized. Like you said, we are done with this back of house area temporarily, the steel guys are up there working around this pie. It's very detailed, it takes a lot of work and a lot of cuts to get that finished up. The cupola just has a couple little finish up items and the roofer can come back here. The metal stud framers are working on this parapet wall on the back side of the transepts and that gets sheeted with plywood so the roofer has something to turn up their flashing to and then the roofer can take it from basically this point and start working back this way towards the nave.

Yeah, so those are pretty large windows, from the ground they don't look very big but once you're up here you can really see how large they actually are. They become much bigger once you get closer. These windows right here are about four foot eight wide and about eleven feet tall. So that really puts it into perspective. The transept windows are similar width and actually the center transept window is six feet wide and twelve feet tall. So from the ground they don't look as big but once you get up here they're very large.

[Bill] With that cupola being at you know 100 feet to the peak what size of lift do you have to use to get up there?

[Drew] This blue 135 over here that you can see, that'll get up here and I believe a 120 will get it if you're on the other corner. It's pretty difficult to get it from this side, from the east side. We pretty much can only access it from the west side because of the elevation changes in the earthwork.

[Bill] So a man basket will get your workers up there and then the crane brings all the materials up?

[Drew] Yep and they're actually going to build a level platform kind of to set their materials on so it's not a safety hazard of materials flying off the roof and wanting to slide down the roof. [Bill] Yeah with our Fall Kansas winds that can be a major challenge. [Drew] Absolutely.

“So as you can see a lot’s been done in the last month we still have a lot further to go to dry this project in before winter, as you all heard.

Please continue to pray for this project, in particular for good weather. ”